News

About Xiamen Acrylic

Xiamen Acrylic, the word may sound strange, because it is a new word that has only appeared on the mainland in recent years. Until 2002, it was gradually understood by a small number of people in advertising, furniture, and crafts. "Acrylic" is a transliterated foreign word. The English name is ACRYLIC, which is a chemical material. The chemical name is "PMMA", which belongs to acryl alcohol, commonly known as "specially treated organic glass". Its raw materials are generally used in pellets, plates, pipes and other methods.

Acrylic sheet with plexiglass

"Organic glass" is derived from English Organic Glass. In recent years, in some areas, all transparent plastic plates are collectively referred to as plexiglass. In fact, this is wrong. Acrylic refers to pure polymethyl methacrylate (PMMA) materials, and PMMA plates are called acrylic. Force plate.

Characteristics and benefits of acrylic board

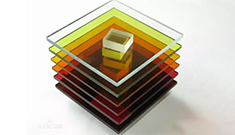

Acrylic has high transparency, 96% light transmittance, and has the reputation of "plastic crystal". And has excellent weather resistance, especially used outdoors, ranking first among other plastics, and has excellent surface hardness and gloss, processing plasticity is large, can be made into a variety of shapes and products required. In addition, the types of plates are complex and rich in color (including semi-bright swatches). Another feature is that thick plates can still adhere to high brightness.

Acrylic history

Acrylic (ACRYLIC), commonly known as special processing plexiglass. Acrylic research and development has a history of more than 100 years. The polymerizability of acrylic acid was first discovered in 1872; the polymerizability of methacrylic acid was known in 1880; the composition method of propylene polypropionate was completed in 1901; the aforementioned composition method was used to test industrial manufacturing in 1927; and the methyl ester industry in 1937 Manufacturing development is successful, and thus enters large-scale manufacturing. During the Second World War, because of its excellent resistance and light transmission, acrylic was first used in windshields of aircrafts, and as a sight glass in the driver's cabin of tanks. The birth of the world's first acrylic bathtub in 1948 brought a new milestone in the use of acrylic.

The use of acrylic

PMMA has the advantages of light weight, low price, and easy molding. Its molding methods include casting, injection molding, machining, and thermoforming. In particular, injection molding can be produced in large quantities, the process is simple, and the cost is low. Therefore, it is used more and more widely, and now it is widely used in the backlight of electronic instruments, car lights, optical lenses, green lighting, etc.

Acrylic is the best new material to make sanitary ware after ceramics. Compared with traditional ceramic materials, in addition to its unparalleled high brightness, acrylic also has the following benefits: good resistance, not easy to break; strong repairability, as long as the soft foam dipped in toothpaste can be used to clean the ware; soft texture, winter There is no icy feeling; the color is colorful, and you can satisfy the characteristics of different levels. The use of acrylic to make basins, bathtubs, and toilets is not only exquisite in style, durable, but also environmentally friendly. Its radiation is almost the same as that of the human body's bones. Acrylic ware first appeared in the United States, and now accounts for more than 70% of the world's shopping malls.

Due to the difficulty and high cost of acrylic production, there are many low-cost substitutes in the mall. These substitutes are also called "acrylic", which is actually a general organic board or composite board (also called sandwich board). General organic boards are cast with ordinary plexiglass cracking materials and pigments. The surface hardness is low, it is easy to fade, and the polishing effect is poor after grinding with fine sand. As long as the surface of the composite board is a thin layer of acrylic, the center is ABS plastic, and it is briefly delaminated due to thermal expansion and contraction during use. True and false acrylic can be identified from the fine color difference and polishing effect of the cross section of the board.

Acrylic

A brief history of plexiglass acrylic (Acrylic) As early as the 20th century, Rohm and Haar first developed the method of using MMA to form acrylic panels, which was later called "Oroglas / Plexiglas".

feature

1. Good weather resistance, acid and alkali resistance, will not cause yellowing and hydrolysis due to sun and rain all year round.

2, long life, compared with other materials, life is longer than three years

3, good light transmission, up to 92%, the required light intensity is small, saving electricity

4. Strong impact resistance, sixteen times that of ordinary glass, suitable for installation in special areas where safety is required

5, excellent insulation function, suitable for various electrical equipment

6, light weight, half lighter than ordinary glass, the load accepted by buildings and supports is small

7, colorful, high brightness, other materials can not be more beautiful

8, strong plasticity, large change in shape, simple processing and molding

9. High recyclability, recognized by increasing environmental protection know-how

10. Convenient maintenance, easy to clean, rainwater can be cleaned naturally, or scrub with Panyu and soft cloth.

Related stories

During World War II, when some planes crashed, the canopy made of plexiglass was blown up, and plexiglass fragments were embedded in the pilot's eyes. After many years, although these fragments have not been removed, they have not caused further inflammation or other adverse reactions in the human eye. This incident happened to show the excellent compatibility of plexiglass and human tissue. It also inspired ophthalmologists, who can make artificial cornea with plexiglass. It has good light transmission, stable chemical properties, non-toxic to human body, simple processing into the required shape, and long-term compatibility with the human eye. Now, artificial cornea made of plexiglass is widely used in clinic.